Carapax

Product videos

CARAPAX® Advantages

- Carapax helps strengthening the total superstructure of the trailer to comply with the EN 12642 XL Regulation. No more horrible accidents of trucks and trailers losing their cargo on the roadway.

- The composite reinforced roof curtain works like a Carapax of a turtle over the trailer top.

- Use your sliding roof like you always did: no cables hanging inside like a spider web.

- Operate quickly and safely: don’t climb up onto the trailer to remove extra steel tubes etc

- Maintenance free! : Carapax is always there at the right tension.

- Comes in 3 versions to suit your needs.

CARAPAX®

A sliding roof is an important part of the total strength of the superstructure. Several types of reinforcements have been tested; e.g. stainless steel wires fixed diagonally under the roof. The wires slide open together with the roof, but they hang like a spider web in the trailers’ loading space.

Besides the high cost of these special stainless steel wires, they cause damage to the aluminum roof rails as all the centrifugal forces are divided over only 2 or 4 points along the aluminum roof rails.

Carapax® is a revolutionary patented concept and works just like a carapax of a turtle over the trailer: the extreme strength of the roof curtain has a positive influence upon the lateral resistance, helping the body structure to comply with the highly demanding EN 12642XL regulation.

No wires are hanging in the loading space of the trailer when the roof is open.

Aramid reinforcement is welded into the roof curtain: aramid fibers are particularly light, yet incredibly strong: five times stronger than stainless steel, heat resistant up to 500° C but softer than your blue jeans!

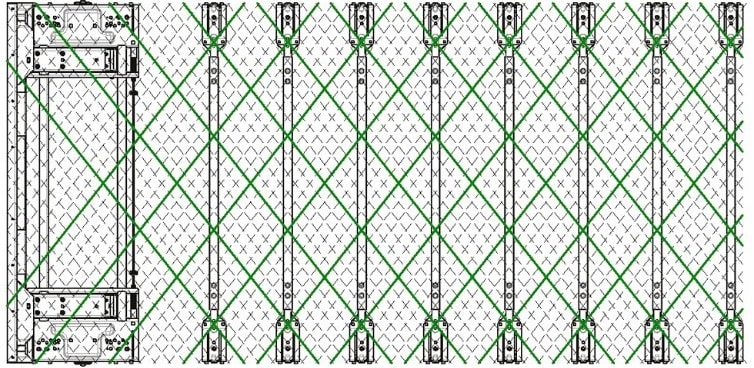

To reinforce the trailer roof, the crossings of the aramid filaments, visible at the underside of the roof curtain, must be secured on every roofstick.

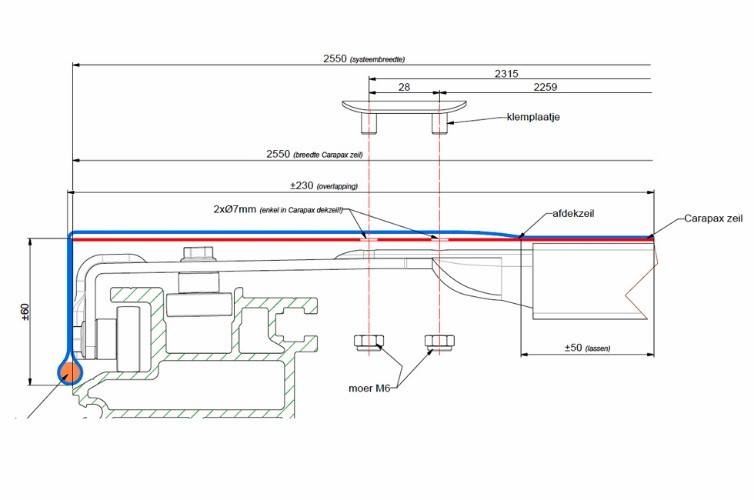

A close-up of the Versus-Omega roof below shows how the CARAPAX® roof curtain is attached to the roofstick.

CARAPAX® RAIL: specifiek voor intermodaal transport.

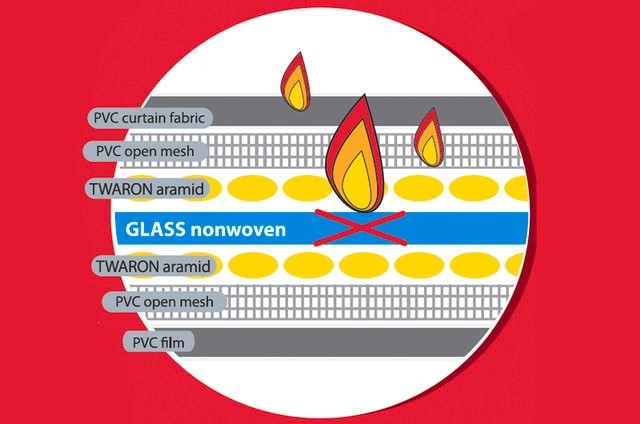

More and more goods are transported over long distances using a combination of road and rail transport using swap bodies or Huckepack trailers. During rail transport sparks drop off the electrical overhead lines and burn holes in the roof curtain. Due to that, cardboard boxes and other goods get wet and are often rejected upon arrival.

To offer an efficient solution to multi-modal transport, the CARAPAX RAIL version was developed by inserting a glass nonwoven inside the Carapax composite reinforcement. Sparks can still burn through the regular PVC top curtain layer, but will be extinguished on the non-flammable glass nonwoven layer. The bottom PVC film will prevent the moisture from dropping through the roof curtain onto the goods.

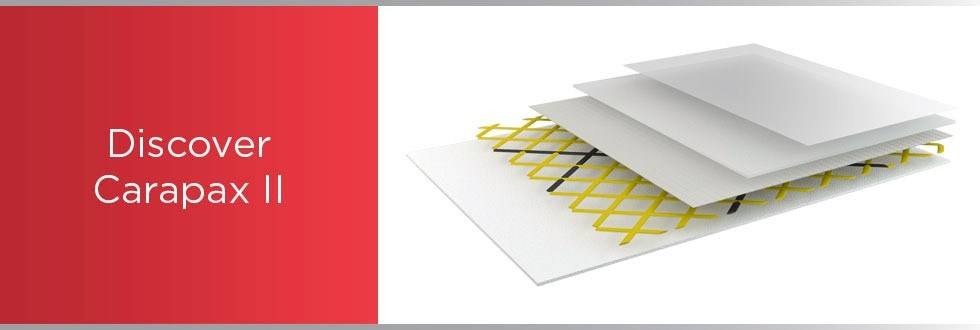

Carapax Ⅱ

The next best thing after Carapax®

Instead of welding the aramid reinforcement structure to a standard PVC curtain fabric, we managed to integrate the aramid reinforcement structure right during the production process of the curtain fabric, resulting in the Carapax® II version, which is thinner, lighter and more translucent than the first generation of the product.

No files available

Almost there!

Please allow us to ask you from which company you are and what your email address is. After filling inh these fields you will have access to the brochure.